Diabase is a type of fine-grained, dark-colored, igneous rock. It is composed primarily of plagioclase feldspar, pyroxene, and sometimes olivine.

Diabase is often found as dikes (tabular bodies of rock that cut across the structure of adjacent rocks) or sills (tabular bodies of rock that parallel the layering of the surrounding rocks) in various geological formations.

The rock has a basaltic composition, meaning it is rich in iron and magnesium. Its texture is typically characterized by small, closely packed crystals, giving it a fine-grained appearance.

The color of diabase can range from dark gray to black. It is known for its durability and is commonly used as a construction material for buildings, monuments, and countertops.

In addition to its use in construction, diabase is sometimes used as crushed stone for road building and railroad ballast. It is also utilized in the production of dimension stone, which is cut and shaped for specific architectural or artistic purposes.

The specific properties of diabase, such as its hardness and resistance to weathering, make it suitable for a variety of practical applications.

Diabase processing involves a series of machines and equipment to extract, crush, grind, and package the diabase into various usable products.

The specific machines used can vary depending on the intended applications, such as construction materials, dimension stone, or crushed aggregates.

Here's an overview of the typical diabase processing machines:

1. Quarrying Equipment:

- Excavators and Bulldozers: Used for removing overburden and extracting diabase blocks from quarries.

- Drilling Equipment: Includes drills for creating blast holes to break up large diabase formations.

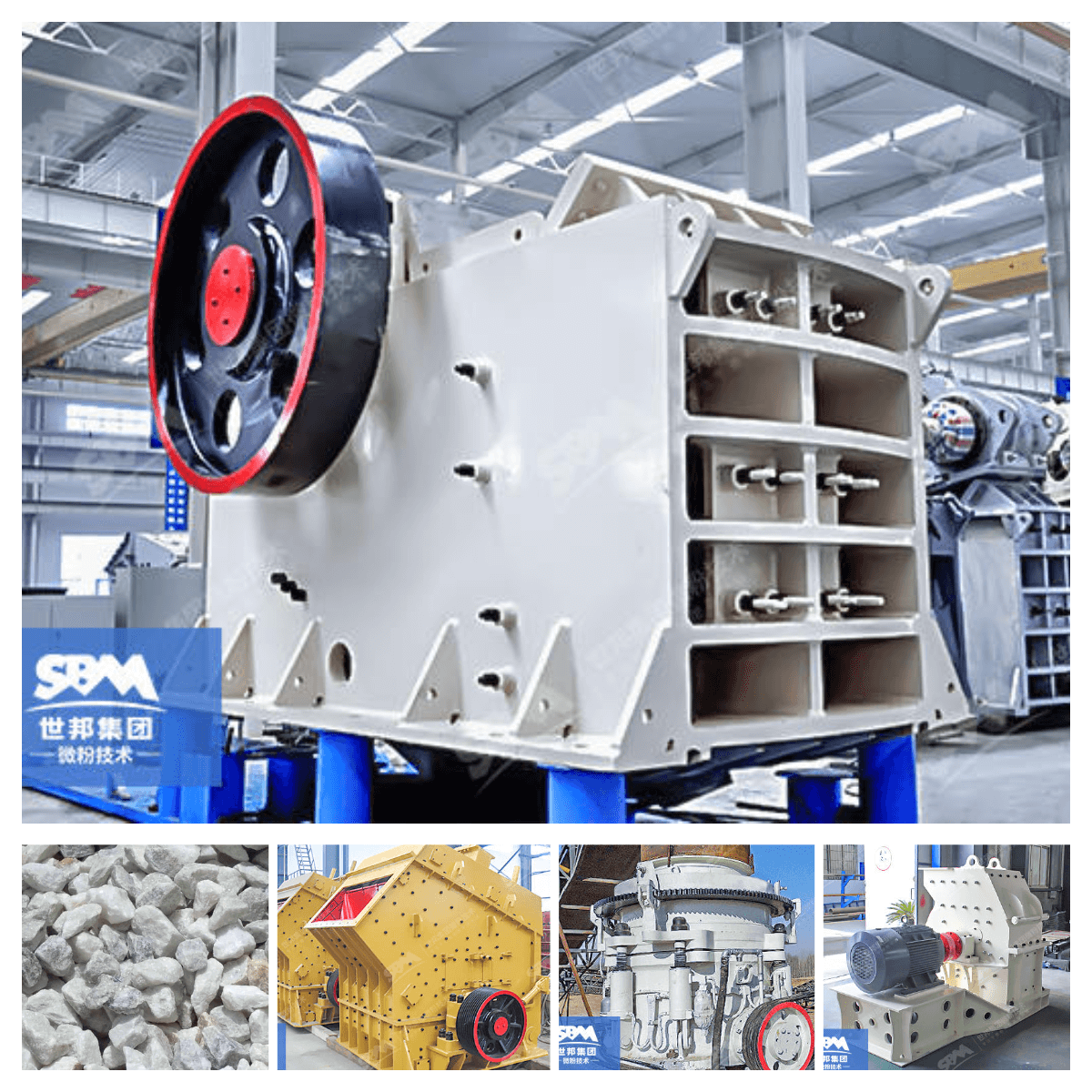

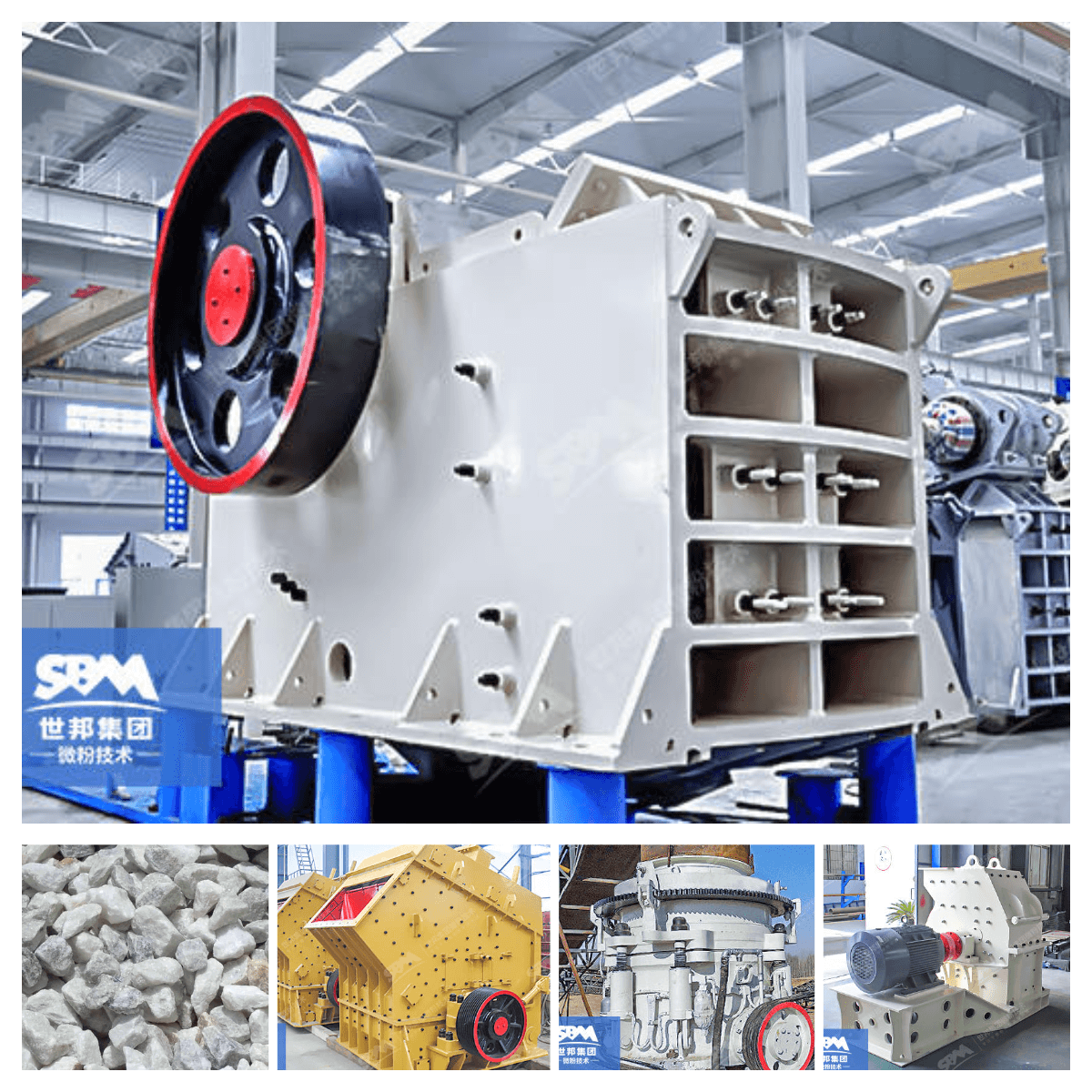

2. Crushing Machines:

Jaw Crusher:

- Function: A jaw crusher is a primary crusher that breaks the diabase into smaller sizes for further processing.

- Operation: The diabase is fed into the jaw crusher, and the movable plate moves against the fixed plate, breaking the material into smaller pieces.

Impact Crusher:

- Function: Impact crushers are used for secondary crushing and can produce cubical-shaped end products.

- Operation: Diabase is fed into the impact crusher, where it is struck by rapidly rotating hammers or bars. This impact breaks the material into smaller pieces.

Cone Crusher:

- Function: Cone crushers are used for secondary and tertiary crushing stages.

- Operation: Diabase enters the cone crusher from the top. The material is crushed between the mantle and the concave, which are the wear-resistant surfaces inside the machine.

3. Screening Equipment:

- Vibrating Screens: Separate crushed diabase into different particle sizes. Used in aggregate production to classify materials.

4. Grinding Mills:

Ball Mill:

- Function: Ball mills are used for coarse grinding as well as fine grinding and mixing of materials.

- Operation: Diabase, along with grinding media, is introduced into the rotating drum of the ball mill. The impact and friction between the balls and the diabase grind the material.

Vertical Roller Mill :

- Function: Vertical roller mills are used for grinding diabase into fine powder.

- Operation: Diabase is fed through a central feed pipe to the grinding table where it is pulverized between the table and the rollers.

Raymond Mill:

- Function: Raymond mills are used for grinding materials into fine powder.

- Operation: Diabase is fed into the mill and is crushed by the grinding rollers. The powder is then separated by the analyzer and collected by the cyclone collector.

Ultrafine Mill:

- Function: Ultrafine mills are designed for producing very fine particles.

- Operation: Diabase is ground to ultrafine sizes by high-speed rotation of the grinding elements. Air classifiers are often used to control particle size distribution.

Hammer Mill:

- Function: Hammer mills can be used for both coarse and fine grinding.

- Operation: Hammers or blades rotate rapidly to impact and grind the diabase into smaller particles.

5. Crushing and Screening Plants:

- Mobile Crushers and Screens: Used in on-site processing, especially in construction projects where diabase is crushed and screened directly at the quarry.

6. Bagging and Packaging Machines:

- For Finished Products: Equipment to package crushed diabase, aggregates, or finished products for distribution.

7. Environmental Control Systems:

- Dust Collection Systems: Essential for controlling airborne dust generated during crushing and grinding operations.

- Water Sprinkler Systems: Used to suppress dust and control emissions in various processing stages.

8. Material Handling Equipment:

- Conveyors and Elevators: Transport diabase between different processing stages and facilitate the movement of materials within the processing plant.

These machines work together in a coordinated manner to process diabase from the quarry to the finished products. The selection of specific machines depends on the nature of the diabase deposit, the desired end products, and the overall processing plant design. Additionally, adherence to safety and environmental regulations is crucial throughout the diabase processing operations.