The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

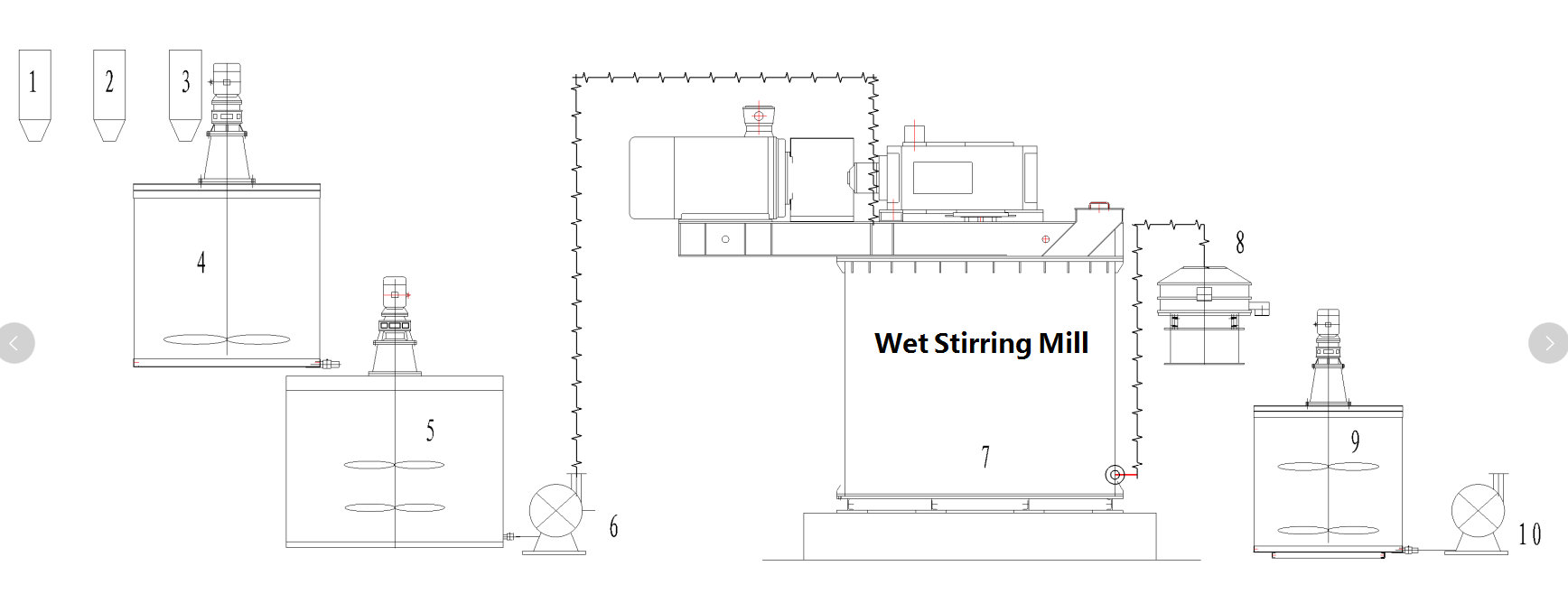

D90 <2 micron

Capacity: 0.6-5 t/h

Models: LXMC1000 LXMC3600 LXMC5600

Applicable materials: kaolin, coal-water slurry, mica, barite, ilite, gypsum, rare earth, magnesium oxide, aluminum oxide, red iron oxide, magnetic materials and So on.

Product features: Ultra fine powders, the finnest powders reach t o 2 micron with content 90% for milling one time.

| Technique | Single mill | Two mills in Series | |

| Powder finness -2 micron | D60 | D90 | D95 |

| Solid content | 70%-75% | 70%-75% | 70%-75% |

| Capacity per hour (dry materials) | 1.4-1.8 | 0.6-0.8 | 0.7-0.9 |

| The dosage of dispersants(Kg/t) | 4 | 10 | 14 |

| Grinding meson balls loss(Kg/t) | 0.2-0.4 | 0.5-0.6 | 0.8-1.2 |

| Power consumption(KW/t) | <45 | <130 | <170 |

| Technique | Single mill | Two or more mills in series | ||

| Powder finness -2 micron |

D60 | D90 | D95 | D98 |

| Solid content | 70-76% | 70-76% | 70-76% | 70-76% |

| Capacity per hour (dry materials) | 3-3.8 | 1-1.5 | 1.8-2.2 | 1.5-1.8 |

| The dosage of dispersants(Kg/t) | 4 | 8 | 12 | 15 |

| Grinding meson balls loss(Kg/t) | 0.3-0.4 | 0.5-0.6 | 0.8-1.0 | 0.8-1.2 |

| Power consumption(KW/t) | <40 | <125 | <145 | <180 |

| Technique | Single Mill | Two or more mills in series | |

| Main unit quantity | One mill | Two mills | Three mills |

| Solid content | 70%-76% | 70%-76% | 70%-76% |

| Powder finness -2 micron | D60 | D75 | D98 |

| Capacity per hour (dry materials) | 4.5-5 | 4.5-5 | 4.5-5 |

| The dosage of dispersants(Kg/t) | <5 | <6 | <15 |

| Grinding meson balls loss(Kg/t) | 0.3-0.4 | 0.4 | 1-1.2 |

| Power consumption(KW/t) | <40 | <50 | <185 |

India

India

Material: Limestone

Fineness:800 mesh

Capacity: 5 t/h

Vietnam

Vietnam

Material: calcium carbonate

Fineness:2500 mesh

Capacity: 10 t/h

China

China

Material: Bentonite

Fineness:200 mesh

Capacity: 10-15 t/h

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.