Screw conveyor is a kind of machinery that uses motor to drive screw rotation and push materials to achieve the purpose of conveying.

It can be transported horizontally, obliquely or vertically, and has the advantages of simple structure, small cross-sectional area, good sealing, convenient operation, easy maintenance, convenient closed transportation and so on.

LS screw conveyor is the updated model of the GX type screw conveyor. The whole conveyor is reliable, durable, adaptable, easy to install. It is suitable for conveying powder, granular, and block materials (temperature <200C), such as coal powder, coal ash, argil, sand, cement, carbamide, etc. The screw conveyor is not only used for the concrete batching plant, bituminous concrete batching, but also for the chemical, building, food, metallurgy, and so on.

Features

●Compared with GX type screw conveyor, LS screw conveyor eliminates the possibility of reducing bearing life because of poor seal and material leakages, heading and rear bearings are removed outside the frame.

●Simple structure, small floor space, low noise, good sealing, easy operation, and maintenance.

●High applicability, convenient feeding inlet and discharging outlet, easy for multi-point feeding and discharge materials.

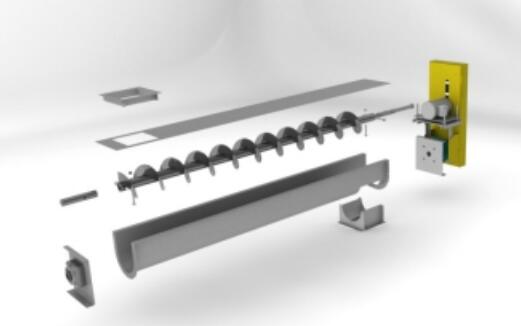

Working Principle

Screw conveyor consists of a shaft with a spiral blade and chute. The Shaft is installed at both ends of the chute bearing base through bearing. The shaft head on one side of the shaft is connected with the driving device. There are feeding inlets and discharging outlets on the top and bottom of the chute. The working principle is as follows.

Materials get into the conveyor through a feeding inlet. Subject to the reverse thrust of the screw blade, the materials can rotate with the shaft for the radial force of thrust and friction between blade and material. As a result of the material itself gravity and friction between chute and materials, the materials do not rotate with a spiral blade but move along the chute on the effect of the axial thrust of blade radial thrust force. Materials move forward in spiral form, which is moving forward accompanied with tumbling motion in the circumferential direction.

Product Specifications

| Model |

LS159 |

LS219 |

LS250 |

| Diameter(mm) |

159 |

219 |

250 |

| Screw pitch (mm) |

159 |

219 |

250 |

| Rotate speed (r/min) |

83 |

83 |

90 |

71 |

| Conveying Capacity (m³ /h) |

2-6 |

5-12 |

22 |

18 |

NOTE: The power of the screw conveyor varies according to the conveying distance.

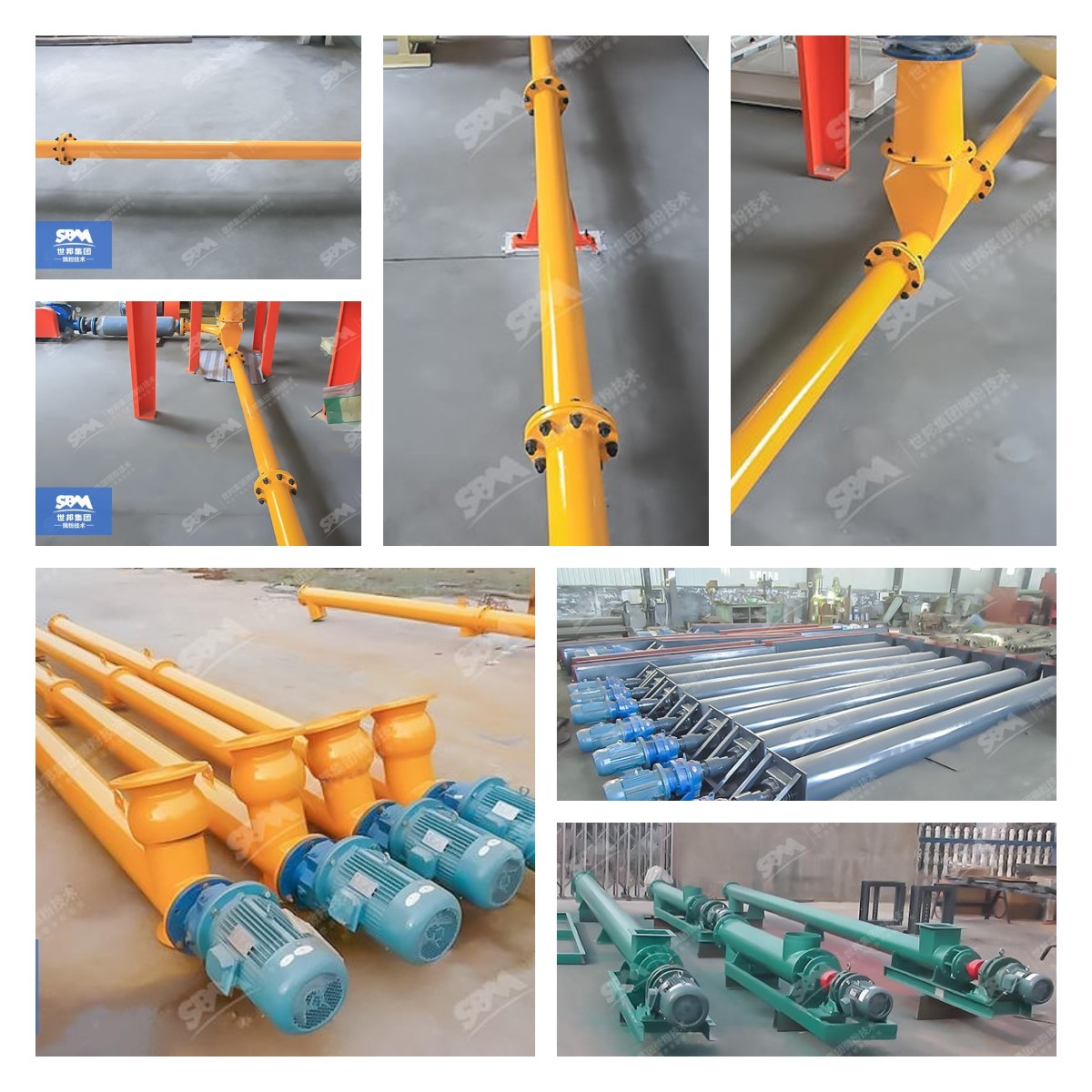

Images of screw conveyor

WHO WE ARE?

SBM Ultrafine Powder Technology Co., Ltd. is one of the premier manufacturers for equipment in the mining, grinding, coating,packing, recycling and process industries.

With SBM Ultrafine Powder Technology unique knowledge and innovative solutions, SBM helps many customers improve their operational efficiency, reduce risks and increase profitability.

SBM Ultrafine Powder Technology products can be divided into

crushing equipment, grinding equipment, drying equipment, screening equipment, conveying equipment and

auxiliary equipment.

SBM Ultrafine Powder Technology products have passed the quality system certification of ISO9001:2008, and the European CE certificate.

SBM sincerely welcome local distributors join us together to shape SBM Ultrafine Powder Technology brand and delivery high value-added equipment products in the global market around world.

SBM Ultrafine Powder Technology is an international high-tech enterprise which integrates the research and development, production and sales.

HOW TO BUY?

- 1. Engineering project design

- 2. Equipment purchasing and manufacturing

- 3. Engineering project construction

- 4. Installation and Commissioning service

- 5. After-sales service

WHICH MODELS CAN BE SELECTED FOR PROCESSING ULTRAFINE POWDER?

HGM grinding mill: 74-5 micron(200-2500 mesh); D97=5 micron

CLUM vertical roller mill: 20-5 micron(600-3000 mesh); D50=2 micron D97=4 micron

HOW TO GET THE LATEST QUOTATION?

You can leave a message online or contact

SBM Ultrafine Powder Technology directly:

WhatsApp: +8613512155195

India

India

Vietnam

Vietnam

China

China