The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

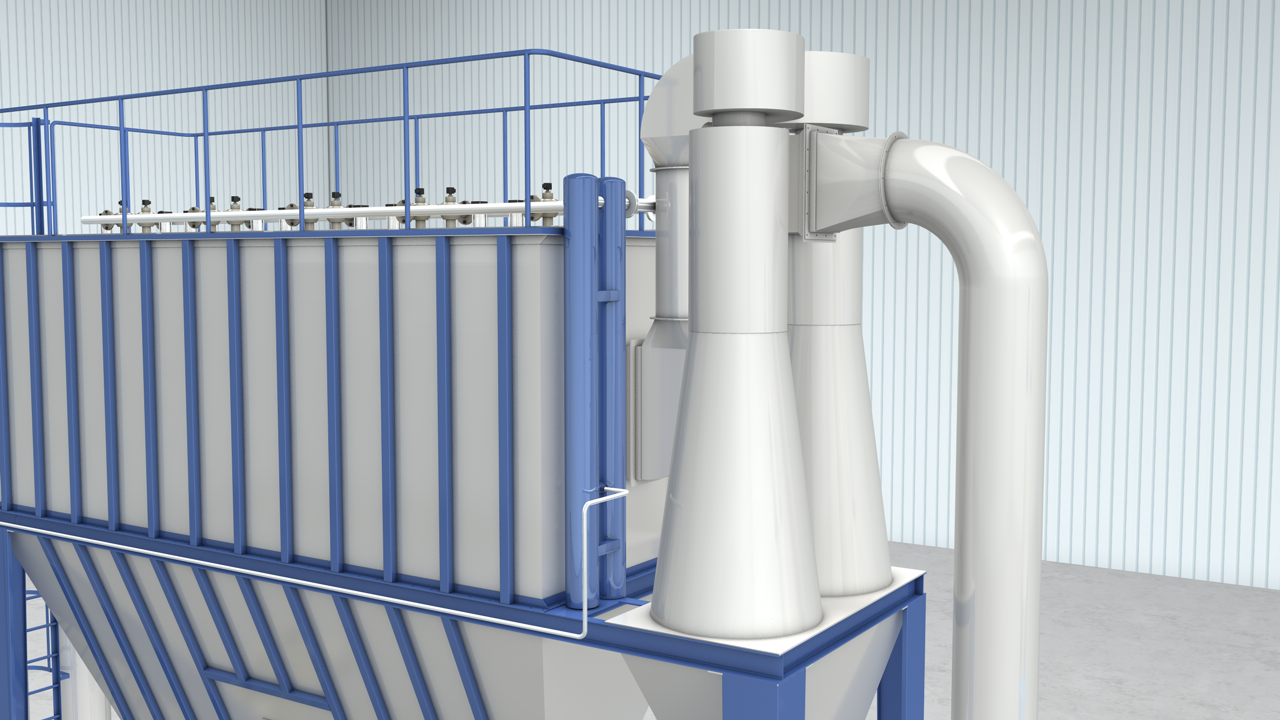

Applicable materials: DMC pulse bag filter is suitable for capturing fine, dry, non-fibrous dust.

Product features: High dust removal efficiency

| Model | DMC64 | DMC72 | DMC84 | DMC96 | DMC108 | DMC120 | DMC160 |

| Filter Area (㎡) | 45 | 54 | 63 | 72 | 81 | 90 | 126 |

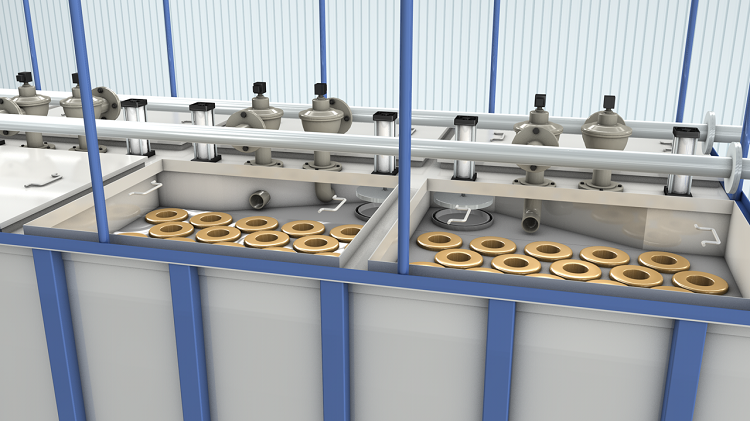

| Filter Bag Quantity (PCS) | 64 | 72 | 84 | 96 | 108 | 120 | 160 |

| Filter Bag Size (mm) | φ130x2000 | ||||||

| Air Volume (m³/h) | 5400-10800 | 6480-12960 | 7560-12960 | 8640-17280 | 9270-19440 | 10800-21600 | 11000-21600 |

| Temperature (Celsius) |

<120oC | ||||||

| Device Resistance (Pa) | 1200Pa-1500Pa | ||||||

| Dust Collector Efficiency (%) | 99%-99.5% | ||||||

| Pulse Pressure (MPa) | 2-4m/min | ||||||

| Air Compressed Volume (m³/min) | 0.5-0.7 | ||||||

| Filter Wind Velocity (m/min) | 0.2-0.8 | 0.25-1 | 0.3-1.2 | 0.3-1.3 | 0.4-1.5 | 0.4-1.7 | 0.165-1.7 |

| Electromagnet Pulse Valve Quantity (PCS) | 10 | 12 | 14 | 16 | 18 | 20 | 20 |

| Measurement (mm) | 1700*1700* 4750 | 1900*1700* 4750 | 2400*1550* 4750 |

2400*1700* 4750 | 2400*1850* 4750 |

2400*2000* 4750 |

3230x2100x4750 |

| Discharge Valve Motor (Power) | 0.75KW |

||||||

1. Frequently check the operation of control valve, pulse valve and timer.

The failure of rubber diaphragm of pulse valve is a common fault of bag filter, which directly affects the ash cleaning effect. The equipment belongs to the external filter type, and the bag is equipped with a skeleton. Check whether the parts fixing the filter bag are loose and whether the tension of the filter bag is appropriate. Whether the support frame is smooth to prevent abrasion of the filter bag. Compressed air is used for ash cleaning. Therefore, it is required to remove oil mist and water droplets, and the oil-water separator must be cleaned frequently to prevent movement mechanism failure and filter bag blockage.

2. Whether the treatment air volume and the pressure and temperature at each test point are consistent with the design.

3. For the installation of filter bag, whether there is bag falling, loosening and wear after use can be judged by visual inspection of the discharge of chimney after operation.

4. Prevent condensation

During use, prevent the gas from cooling below the dew point in the bag room, especially when using the bag filter under negative pressure. Because air often leaks into its shell, so that the gas temperature in the bag chamber is lower than the dew point, the filter bag will be damp, so that the dust is not loose, but sticky attached to the filter bag, blocking the fabric holes, resulting in ash removal failure, resulting in excessive pressure drop of the dust collector, unable to continue to operate, and some paste bags can not remove dust.

To prevent condensation, the temperature of the gas in the dust collector and its system must be kept 25 ~ 35 ℃ higher than its dew point (e.g. the dew point temperature of the kiln mill integrated machine is 58 ℃, and the operating temperature should be more than 90 ℃), so as to ensure the good use effect of the filter bag.

India

India

Material: Limestone

Fineness:800 mesh

Capacity: 5 t/h

Vietnam

Vietnam

Material: calcium carbonate

Fineness:2500 mesh

Capacity: 10 t/h

China

China

Material: Bentonite

Fineness:200 mesh

Capacity: 10-15 t/h

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.