The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

Output Size: 5-20 mm

Feed size.: <350 mm

Capacity: 5-30 t/h

Applicable materials: The hammer crusher is suitable for crushing medium-hard materials such as limestone, slag, coke, coal and other materials in cement, chemical, electric power, metallurgy and other industrial sectors.

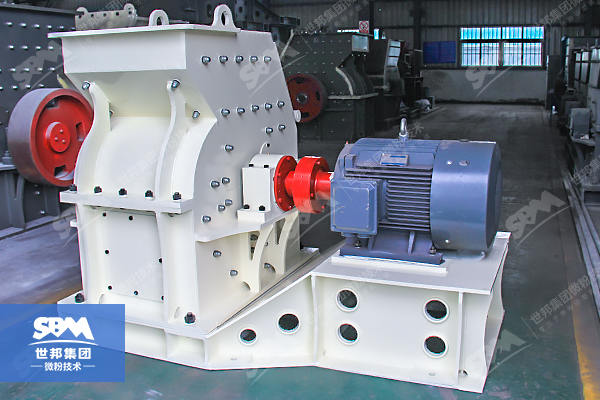

Product features: PC hammer crusher is a kind of industrial machinery, the principle is to crush the material by the collision of the high-speed rotating hammer body and the material.

The hammer crusher stone breaker is a one-stage crusher that directly crushes materials with a maximum particle size of 600-1800 mm to 25 or below 25 mm.

Hammer crusher stone breaker is a kind of industrial machinery, the principle is to crush the material by the collision of the high-speed rotating hammer body and the material.

It is suitable for mining, cement, coal, metallurgy, building materials, highway, combustion, and other departments to finely crush medium-hard and brittle materials.

Hammer crusher stone breaker is used for various ores with compressive strength not exceeding 100MPa and moisture content less than 15%.

The hammer crusher stone breaker is used to crush various medium-hard and weakly abrasive materials. The compressive strength of the material does not exceed 100MPa, and the moisture content is less than 15%. Such as coal, salt, chalk, gypsum, bricks, limestone, shale, etc.

It can also be used to crush wood, paper, or crushed asbestos cement with a strong fiber structure, elasticity, and toughness to recycle asbestos fibers.

In addition, the hammer crusher stone breaker can not only be used in crushing production lines, sand production lines, but also in the beneficiation production line instead of cone crushers.

The hammer crusher stone breaker is suitable for crushing medium-hard materials such as coal, limestone, gypsum, slag, coke, coal, soft refractory materials and other materials in cement, chemical, electric power, metallurgy and other industrial sectors.

Hammer crusher stone breaker is mainly composed of frame, rotor, supporting iron, and grate.

The frame is divided into upper and lower parts, which are welded after cutting steel plates. The frame lining is made of high manganese steel, which can be replaced after wear.

The rotor is composed of the main shaft, a turntable, a pin, and a hammer, and the turntable, a pin, and a hammer are regularly combined in the main shaft. The motor drives the rotor to rotate rapidly in the crushing cavity, and the hammer spreads outward under the centrifugal force of the rotor rotation.

The bulk material entering the crusher through the feed port is hammered, impacted, cut, and ground into small sizes at high speed.

After crushing, the qualified materials are screened out from the gap of the grate, and the unqualified materials are left in the crushing cavity for further hammering and grinding until they reach the standard particle size.

The size of the final product can be adjusted by replacing the furnace bar. The gap between the rotor and the grate can also be adjusted according to different requirements.

The overall design has the advantages of beautiful appearance, compact structure, few wearing parts and convenient maintenance. It is an upgraded product.

It has the characteristics of a simple structure, a large crushing ratio, and high production efficiency. It can be crushed in dry and wet forms.

The crushing ratio is large, the production efficiency is high, and the applicability is strong. The required particle size can be adjusted according to customer requirements.

There is no screen mesh bottom, no requirements for the moisture content of the material, there is no problem of clogging the sieve plate, and there is no problem that the material cannot be discharged in time and repeated crushing; the structure of the hammer breaks the machine body to be sealed, which solves the dust pollution in the crushing workshop. And the problem of body dust leakage.

The bearing box is all made of steel castings and fixed with four screws, which is scientific and practical; the working hammer is cast with a new process, which is wear-resistant and impact-resistant.

The working hammer is cast with a new technology, which is wear-resistant and impact-resistant.

The required granularity can be adjusted according to customer requirements.

The structure of the machine body is sealed, which solves the problems of dust pollution and ash leakage of the machine body in the crushing workshop.

The overall design has the advantages of beautiful appearance, compact structure, few wearing parts, and convenient maintenance. It is an upgraded product.

| Model | PC400x300 | PC600x400 | PC800x600 |

| Rotor diameter /mm | 400 | 600 | 800 |

| Rotor length /mm | 300 | 400 | 600 |

| Rotor speed r/min | 1100 | 1000 | 900 |

| Max. feeding size /mm | <100 | <220 | <350 |

| Ouput size /mm | 5-10 | 5-15 | 5-20 |

| Capacity T/h | 5-13 | 10-20 | 18-30 |

| Motor power /KW | 11 | 18.5 | 45 |

| Number of hammer /piece | 16 | 20 | 28 |

| Weight /T | 0.8 | 1.8 | 2.8 |

| Overall dimension L*W*H/mm | 900*670*860 | 1200*1050*1200 | 2360*1490*1415 |

Answer:

When the clearance between the hammer head and the screen bottom of the screen bar of the hammer crusher is too large, the hammer head and the screen bottom of the screen bar and the hole diameter of the screen bottom are large, it is suitable for coarse crushing production of materials; Otherwise, it is suitable for fine crushing production. If the gap and the aperture size of the screen bottom are ignored in the specific production, it will have an adverse impact on the production. Therefore, in the actual operation and production, the internal structure of the hammer crusher should be reasonably adjusted according to the production needs, and the production capacity will be higher if the equipment is in a good operating environment.

1. During coarse breaking production: if the hole diameter of the screen bottom meets the production requirements of the equipment, but the gap between the hammer and the screen bottom is too small, it is easy to cause the material to be stuck in the screen strip and damage the screen strip and screen bottom; When the clearance between the hammer head and the screen bottom is too large, but the hole diameter of the screen bottom is too small, it will cause the feeding stagnation of the hammer crusher, and even cause the motor to burn out, resulting in the stagnation of production.

2. During fine crushing production: if the hole diameter of the screen bottom of the hammer crusher meets the requirements, but the gap between the hammer head and the screen bottom is large, it will also lead to difficult material feeding and even burn the motor; When the hole diameter of the screen bottom is too large and the gap between the hammer head and the screen bottom is too small, the hammer crusher manufacturer will not meet the production design requirements, the particle size of the finished product does not meet the production needs, resulting in a waste of equipment and materials.

Answer:

1. To enter the work site, you must wear a protective cap, work clothes and anti-skid shoes.

2. Check the physical condition of the maintenance personnel, drinking alcohol is strictly prohibited, and those who are physically fatigued are allowed to work.

3. When using lighting during inspection and repair, use non-open wire ends, undamaged cables for wiring, and lamp holders need to wear protective covers.

4. The use of oxygen and electric welding for maintenance must strictly abide by the corresponding operating procedures.

1. The power supply must be cut off before the overhaul, and a warning sign of "No switch on, someone working" should be hung on the control cabinet, and it should be taken back immediately after the overhaul is completed.

2. Before overhauling, ensure that no one is working in the preheater and the kiln. If the kiln needs to be changed, wait for all the personnel in the grate cooler to evacuate.

3. Clean up the materials at the crusher mouth before maintenance.

1. Put the rotor disc of the crusher to a suitable position and fix it.

2. Oxygen cuts the hammer head fixing bolts and draws them out; cut clean the protrusions caused by wear on both sides of the hammer head.

3. Hold the hammer well and drive out the pin shaft. If the pin shaft is bent and cannot be drawn out, cut it with oxygen and take it out.

4. Move the removed hammer head, pin shaft, fixing sleeve, and bolt to one side without affecting the construction.

5. Lift the new hammer head to the mouth of the crusher. If you use a pipe or crowbar or other hammer head, you need to hold the hammer head well to prevent it from slipping to one side and hurt people.

6. Build a pipe from the grate bed to the rotor of the crusher. Two people hold the hammer and push it to a suitable position. Pay attention to the hammer head facing down to prevent the hammer from falling down and hurting people; the other person installs the fixing sleeve and the pin. , Wear bolts.

7. When replacing the hammer heads, check the weight of the hammer heads one by one, try to ensure the balance of the rotor, and check after installation.

8. After the hammer is installed, all bolts are spot welded and fixed.

9. Turn the rotor body to observe the gap between the hammer head and the sieve plate, and adjust the sieve plate if necessary.

After the above work is done, remember to clean up the site, wait for all the staff to evacuate, power on and test the machine, observe the current and vibration conditions, if there is any abnormality, deal with it in time.

India

India

Material: Limestone

Fineness:800 mesh

Capacity: 5 t/h

Vietnam

Vietnam

Material: calcium carbonate

Fineness:2500 mesh

Capacity: 10 t/h

China

China

Material: Bentonite

Fineness:200 mesh

Capacity: 10-15 t/h

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.