The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

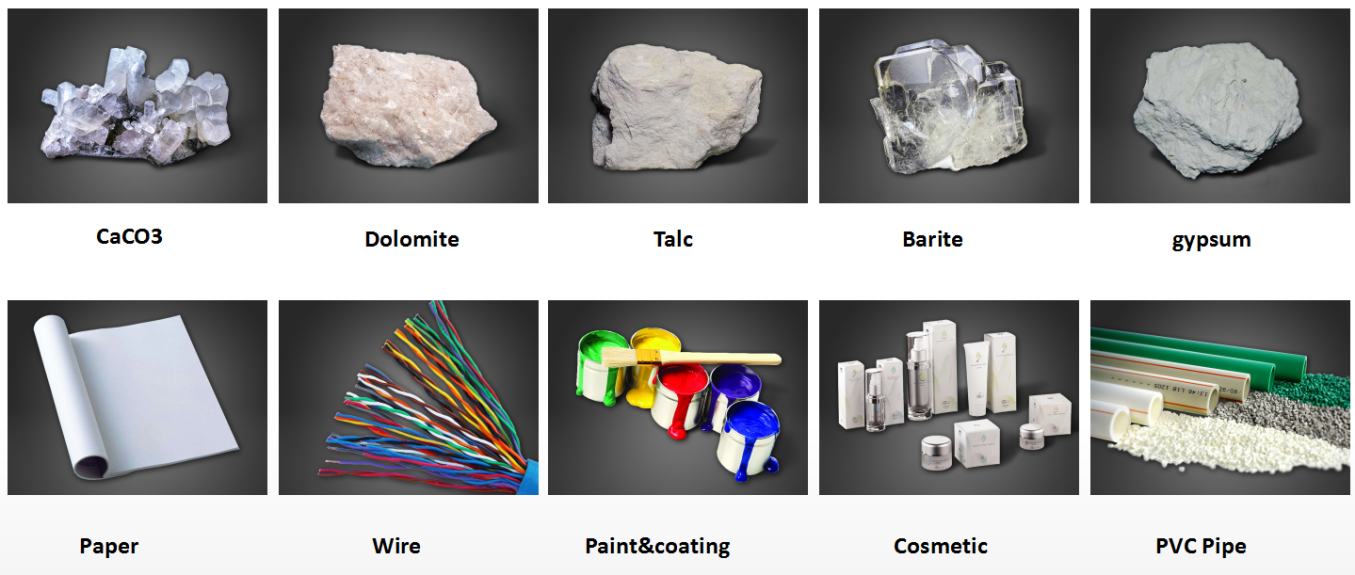

Applicable materials: calcium carbonate, limestone, gypsum, kaolin, bentonite, calcite, dolomite, talc, mica, barite

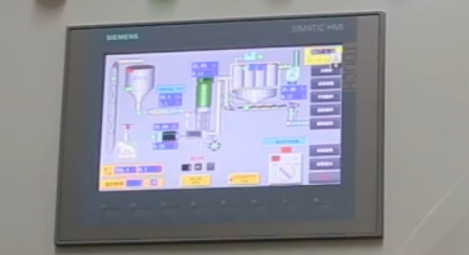

Product features: High Efficiency| Long life cycle of spare parts| High safety and reliability| High fineness, flexible adjustment| Environment-friendly| Advanced intelligent speed control device.

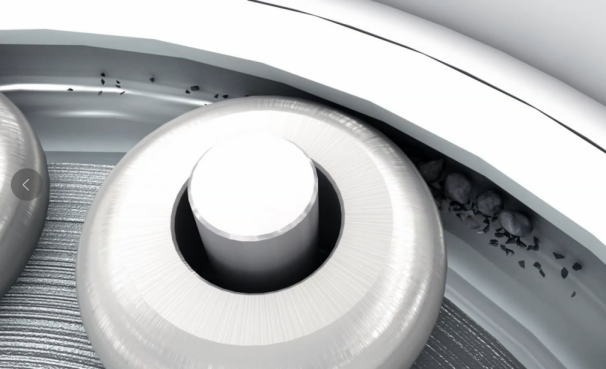

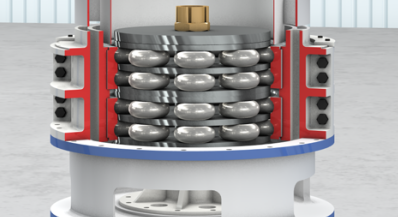

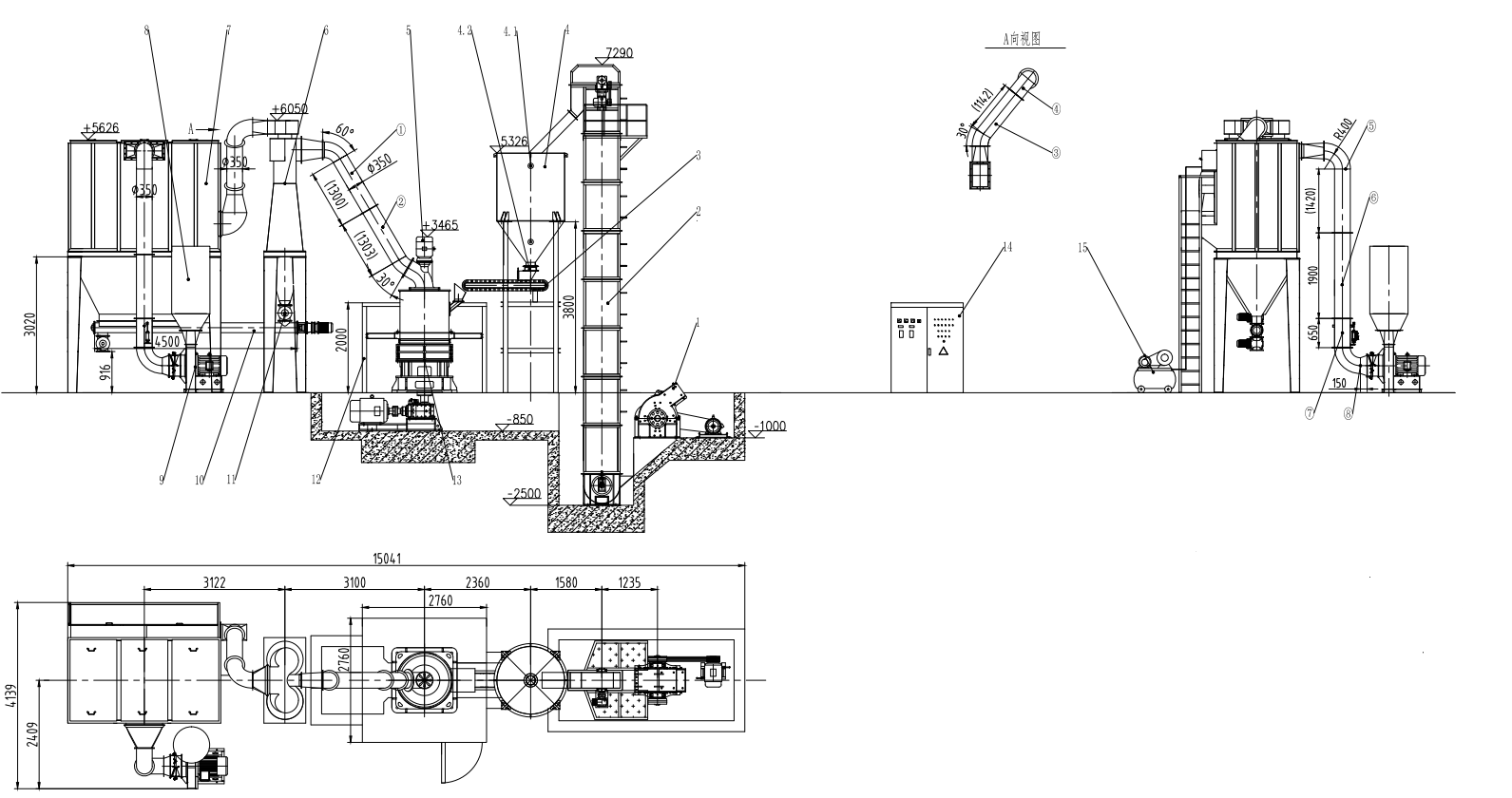

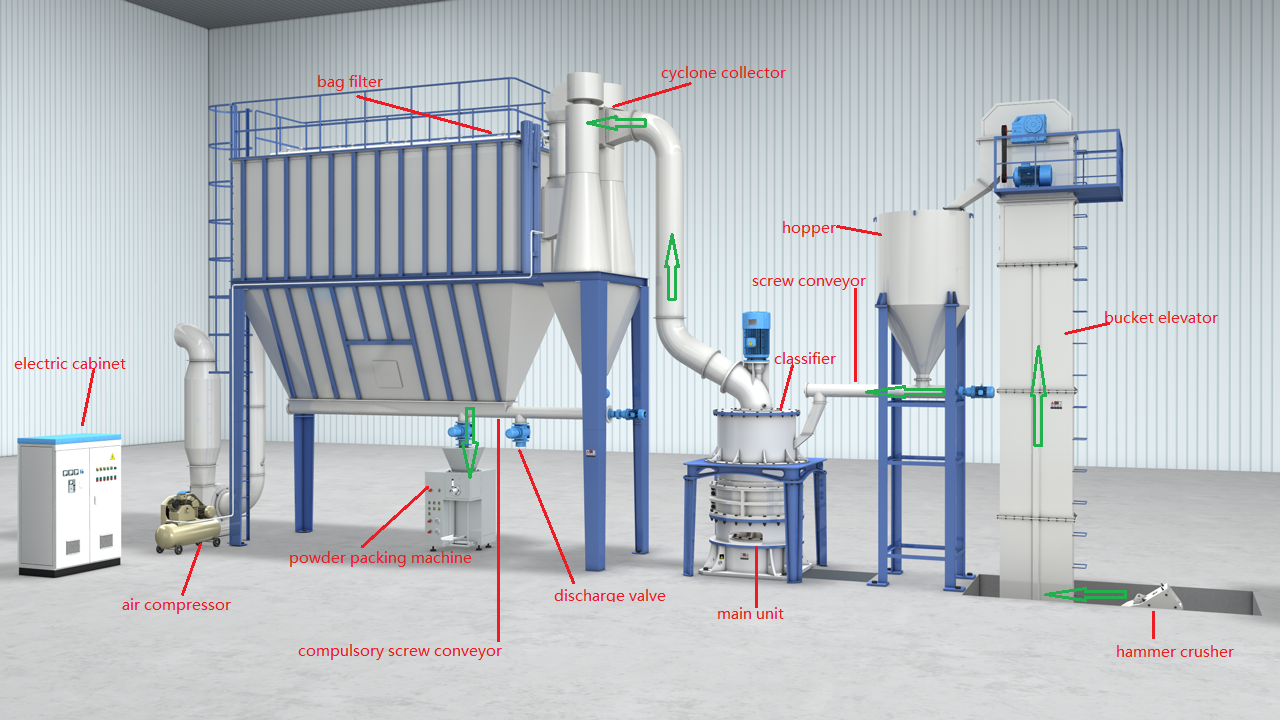

HGM series micro powder grinding mill mainly consist of main unit, classifier, powder collector(all models removed out except HGM80), bag filter, draft fan, muffler, sound-proof room, crusher, bucket elevator, storage hopper, and belt feeder. After crushed by crusher, the large materials become small ones and are sent to storage hopper by bucket elevator, and then evenly sent to the upper distribution plate of the turn plate by belt feeder and sloping feeding pipe. When the grinding mill is working, all the grinding rollers are rolling in the ring, and the materials are driven to the edge of the turn plate by the centrifugal force and fall down into the grinding chambers where the materials are repeatedly pressed, crushed and grind by the rollers.

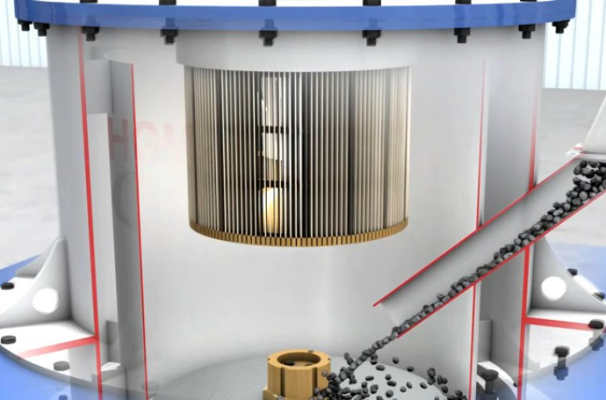

The high-pressure air fan constantly inhales air within the grinding mill and, in turn, the airflow with crushed materials are brought to the classifier whose high-speed impeller will screen the airflow: the unqualified particle size will fall and return to the mill for being reground while the qualified particle size mixed with air will go into the cyclone powder collector. Most of the qualified powders will fall and exit from the discharging valve at the bottom; a small proportion of the fine powders, with airflow, moves to the bag filter, and clings to the surface of the filter bags. At the same time, the fine powders clinging to the surface fall down by the sudden vibration of the filter bags, which is caused by the instantly ejected high-pressure gas controlled by the pulse valve. The materials from the above two lots are sent by the conveyor at the bottom to get finished powders packed. In addition, filtered clean air will be emitted from the air outlet of muffler in the end.

One set HGM80 micro powder grinding mill

| Model | HGM80 |

| Roller Number (pcs) | 21 |

| Grinding layer | 3 |

| Ring size (mm) | Ф880*360 |

| Roller Size(Out Dia*Height)(mm) | 228*88 |

| Main Shaft Speed(r.p.m) | 230-240 |

| Max feeding Size(mm) | 20 |

| Finished size (micron/mesh) | 74-5 (200-2500) |

| Capacity (t/h) | 0.5-5.5 |

| Model | PC600*400 |

| Rotor diameter*Length (mm) | 600*400 |

| Rotor speed (r/m) | 1000 |

| Max Feed Size (mm): | <220 |

| Hammer No.(pc) | 20 |

| Output Size (mm): | <15 |

| Motor Power (kw): | 18.5 |

| Dimension (mm): | 1129×1081×1240 |

| Model | TH200*9.79 |

| Capacity(t/h) | 8-15 |

| Length (m) | 9.79 |

| Steel Material | Q235 |

| Drive sprocket ratation speed(r/min) | 63 |

| Motor Power (kw): | 3 |

| Feature&function | Conveying material & cover small space |

| Model | DMC120 |

| Filter Area(㎡) | 110 |

| Filter Bag Quantity(PCS) | 120 |

| Filter Bag Size(mm) | φ150×2010 (105p) φ150×1510 (15 p) |

| Air Volume(m3/h) | ≤12000 |

| Injection pressure | 0.5-0.7Kpa |

| Dust Collector Efficiency(%) | 99.9% |

| Velocity of filtering | ≤1.8m/min |

| Air compressor specification | KSH150D/11KW |

| Interval time of pulse valve | 4S |

| Working time of pulse valve | 0.08S |

| Injection period | 4.08S |

| Number of pulse valve | 15 |

| Concentration of gas discharging | ≤20g/m³ |

| Model | HGM80 |

| Wind Capacity (m3/hr) | 12000 |

| Wind Pressure (Pa) | 9000 |

| Motor ( kw/p) | 45 |

| Rotate speed (r/min) | 2900 |

| Driving way | A |

| static load / dynamic load | 6050/4220 |

| Weight(kg) | 555 |

| Tech Model | DHF-35-630A-45 |

| Working type | absorbing |

| Dimension (mm): | 1294X1157X1076 |

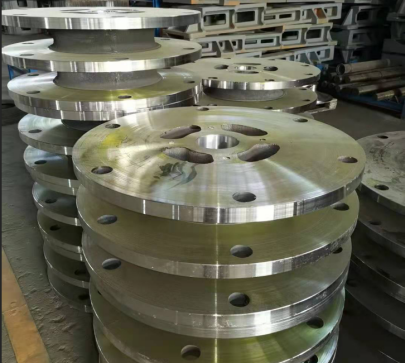

| No. | Name | Size | Material |

| 1 | Roller | Φ228*88mm | Wearable alloy steel 60Si2Mn |

| Actual picture For your reference only |

Remark | ||

|

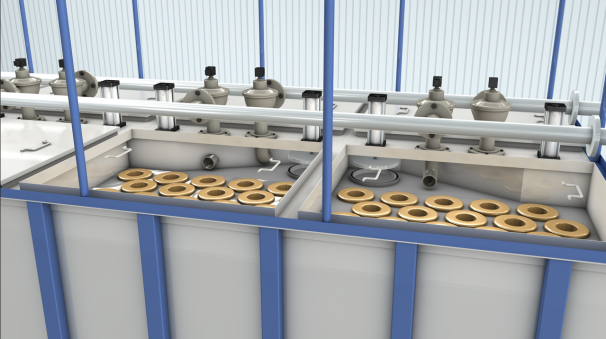

HGM80 model content three grinding layers,each of layer has 7 pcs of roller, totally has 21 pcs of rollers. The lifetime of roller can be 7000-10000 hours working (The data based on domestic calcium carbonate powder factory’s feedback) |

||

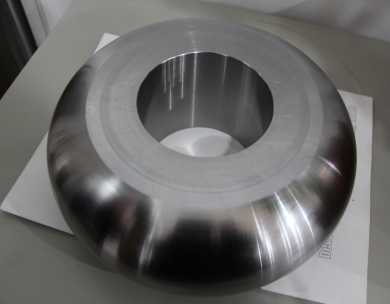

| No. | Name | Size | Material |

| 2 | Ring | Φ880*360mm | Wearable alloy steel 40CrNiMo |

| Actual picture For your reference only |

Remark | ||

|

HGM80 model content 1 pcs of ring The lifetime of ring is similar with roller,which can be 7000-10000 hours working (The data based on domestic calcium carbonate powder factory’s feedback) |

||

| No. | Name | Size | Material |

| 3 | Turn plate | Φ720*386mm | Wearable alloy steel 35CrMo |

| Actual picture For your reference only |

Remark | ||

|

HGM80 model content 1 pcs of turn plate,the lifetime is same with shaft pin.,which can be 5000-6600 hours working (The data based on domestic calcium carbonate powder factory’s feedback) | ||

| No. | Name | Size | Material |

| 4 | Shaft pin | Φ62*386mm | Wearable alloy steel 60Si2Mn |

| Actual picture For your reference only |

Remark | ||

|

HGM80 model content 7 pcs of Shaft pin,the lifetime is same with turn plate.,which can be 5000-6600 hours working (The data based on domestic calcium carbonate powder factory’s feedback) | ||

| No. | Name | Size | Material |

| 5 | Classifier impeller | Φ500*Φ60*415mm | Special wearable alloy steel |

| Actual picture For your reference only |

Remark | ||

|

HGM80 classifier running speed can be 2700rpm at most,the blade number can be customized according to output size requirement.The lifetime is about 10000-20000 hours working (The data based on domestic calcium carbonate powder factory’s feedback) | ||

| Parameters of HGM Series Ultrafine Grinding Mill | |||||||

| Model | HGM80 | HGM80A | HGM90L | HGM100L-Ⅱ | HGM100P | HGM125L | HGM1680L |

| Ring Diameter(mm) | 800 | 800 | 900 | 1000 | 1000 | 1250 | 1680 |

| Ring Number (PCS) | 3 | 3 | 4 | 4 | 4 | 4 | 4 |

| Input Size (mm) | ≤10 | ≤10 | ≤10 | ≤15 | ≤15 | ≤20 | ≤20 |

| Output Size (mesh) | 150-3000 | 150-3000 | 150-3000 | 150-3000 | 150-3000 | 150-3000 | 150-3000 |

| Capacity (t/h) | 0.5-5.5 | 0.5-5.5 | 0.8-6.5 | 1.2-10 | 1.2-11 | 2.5-20 | 5-45 |

| Outlet Size L*W*H (mm) | 8605*4139*6050 | 10454*3393*6626 | 11735*3952*7525 | 14507*3633*7562 | 14362*4200*7562 | 19261*4406*8591 | 25067*5414*9007 |

| Main Motor Power (kw) | 75 | 75 | 55*2 | 132/75*2 | 132/75*2 | 185 | 315 |

India

India

Material: Limestone

Fineness:800 mesh

Capacity: 5 t/h

Vietnam

Vietnam

Material: calcium carbonate

Fineness:2500 mesh

Capacity: 10 t/h

China

China

Material: Bentonite

Fineness:200 mesh

Capacity: 10-15 t/h

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.