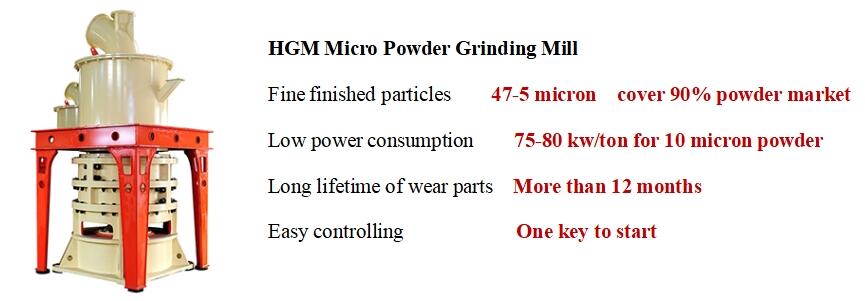

The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

Maxing Feeding Size: 20 mm

Ouput Size: 74-5 micron (200-2500 mesh)

Capacity: 0.5-5.5 t/h

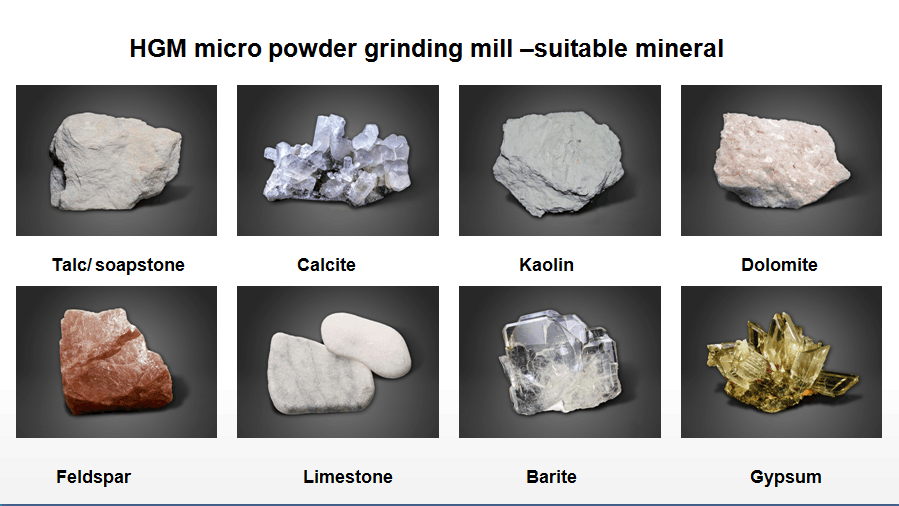

Applicable materials: Calcium carbonate, limestone, kaolin, limestone, calcite, marble, talcum, barite, gypsum, dolomite, bentonite mud, mica

Product features: High Efficiency; Long life cycle of spare parts; High safety and reliability; High fineness, flexible adjustment; Environment-friendly; Advanced intelligent speed control device.

|

HGM100L micro powder mill - calcium carbonate |

||

|---|---|---|

|

Fineness (micron ) |

Capacity(ton / hour) |

Power consumption for one ton powder (kwh /ton) |

|

5 |

1.5 |

125 |

|

8 |

2.2 |

85 |

|

10 |

3 |

63 |

|

15 |

4.5 |

42 |

|

20 |

5.5 |

34 |

|

25 |

7 |

26 |

One set HGM100L ultra fine powder grinding mill installation cover 92 square meter space, 9 meter height . Total production line need 2-3 workers, one for raw material feeding , one for operation and maintenance , the last one for final packing .

Total line machine is closed system ,the bag filters has passed CE&ISO certificate , our bag filter is pulse off-line type, which has many boxes working one by one , you can control the working time lag, when next one working , this worked one can have time to clean itself. By the way, we suggest clients install crushing line outside of factory , because crushing part surely have dust out .

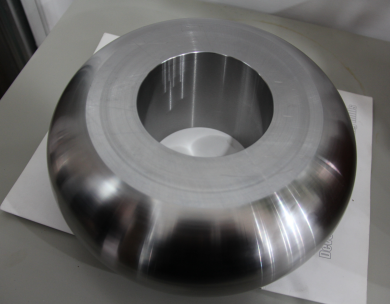

Our wearing parts made by wear-resisting alloy steel, which is designed by our technical department with Bao Group together. The normal wearing parts includes ring, roller, turn plate and shaft pin , normally for grinding calcium carbonate, 10 hours /day, 30days/month, they can work 18-24 months.

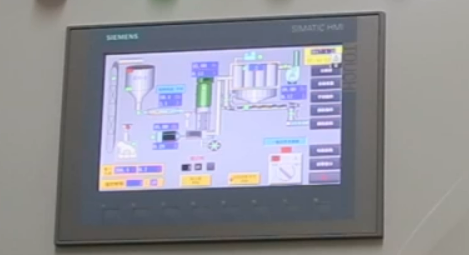

Total production line controlled by PLC (Siemens) brand with KTP touch screen ,which can make one key start and stop . So you no need worry about starting and stopping steps mistakes.

Also, once the hopper has no material for feeding main unit, then main unit will stop automaticly .

Once installation finished, you can store at least four setting data inside PLC soft , for example, you can set 325 mesh, 800 mesh, 1250 mesh and 2500 mesh , once you changing producing between these size , you can only set one key to transfer the producing size , which has made the operation steps very easy to accept .

Under the same finished final size and the same motor power, the capacity of micro powder grinding mill is twice as much as jet mill, mixing grinder and ball mill, and energy consumption decreased 30%.

The ring and roller are forged by special material with high utilization. Under the same grinding material and finish special size, the lifecycle of spare parts is about one year, which is 2-3 times longer than impact mill or turbo mill. Furthermore, the lifetime can reach 2-5 years for grinding calcite carbonate. The lifecycle of spare parts is variable for the material's hardness.

As no rlling bearings or screws in grinding cavity, there are no problems caused by bolts shedding or rapid wear of bearings and seal components.

The final fineness of the grinding materials can be adjusted between 200 meshes and 2500 mesh (74-5 micron).

The application of pulse bag filter and muffler greatly alleviates dust pollution and noise.

Let the material feed into the machine evenly,adjust the main speed to fit for grinded material,the fineness more stable. So as to increase the capacity and efficiency, reduce the power consumption.

| Parameters of HGM Series Ultrafine Grinding Mill | |||||||

| Model | HGM80 | HGM80A | HGM90L | HGM100L-Ⅱ | HGM100P | HGM125L | HGM1680L |

| Ring Diameter(mm) | 800 | 800 | 900 | 1000 | 1000 | 1250 | 1680 |

| Ring Number (PCS) | 3 | 3 | 4 | 4 | 4 | 4 | 4 |

| Input Size (mm) | ≤10 | ≤10 | ≤10 | ≤15 | ≤15 | ≤20 | ≤20 |

| Output Size (mesh) | 150-3000 | 150-3000 | 150-3000 | 150-3000 | 150-3000 | 150-3000 | 150-3000 |

| Capacity (t/h) | 0.5-5.5 | 0.5-5.5 | 0.8-6.5 | 1.2-10 | 1.2-11 | 2.5-20 | 5-45 |

| Outlet Size L*W*H (mm) | 8605*4139*6050 | 10454*3393*6626 | 11735*3952*7525 | 14507*3633*7562 | 14362*4200*7562 | 19261*4406*8591 | 25067*5414*9007 |

| Main Motor Power (kw) | 75 | 75 | 55*2 | 132/75*2 | 132/75*2 | 185 | 315 |

India

India

Material: Limestone

Fineness:800 mesh

Capacity: 5 t/h

Vietnam

Vietnam

Material: calcium carbonate

Fineness:2500 mesh

Capacity: 10 t/h

China

China

Material: Bentonite

Fineness:200 mesh

Capacity: 10-15 t/h

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.