Coal gangue refers to the solid waste generated during coal mining and coal washing processes.

It is a mixture of various substances, including rock, shale, and other impurities that are extracted along with coal from the earth.

The composition of coal gangue can vary depending on the coal seam and mining methods.

A coal gangue processing production line

A coal gangue processing production line typically involves several stages to process the raw coal gangue into various useful products or for disposal.

The specific steps and technologies used can vary depending on the goals of the processing and the desired end products.

Here is a generalized outline of a coal gangue processing production line:

Raw Material Collection:

Coal gangue is collected from coal mines during the mining process. It includes various impurities such as rocks, minerals, and other non-coal materials.

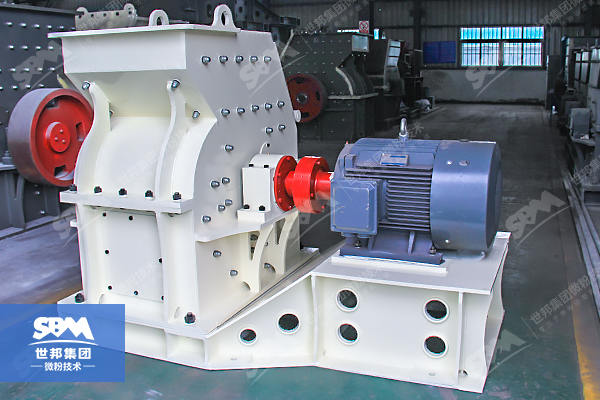

Raw Material Crushing:

The collected coal gangue is crushed into smaller particles to facilitate further processing. Crushing is typically done using crushers as follows:

- Jaw Crushers: These use compressive force to break down the gangue into smaller pieces. Jaw crushers have a fixed jaw and a moving jaw, and the material is crushed between them.

- Impact Crushers: These use impact force to crush the gangue. They can be further categorized into horizontal shaft impactors (HSI) and vertical shaft impactors (VSI), each with its own advantages and applications.

- Hammer Crushers: These use rotating hammers or knives to impact and shatter the gangue into smaller pieces.

Screening:

After crushing, the material is screened to separate finer particles from larger ones.

This step helps in achieving a more uniform size distribution.

Grinding:

Some coal gangue processing lines may involve grinding the material into finer particles.

Grinding can enhance the utilization of gangue in certain applications, such as in the production of building materials.

The following are some commonly used coal gangue grinding machines:

- Ball Mills: These are cylindrical devices that rotate around a horizontal axis, partially filled with the material to be ground and grinding media (e.g., steel balls). The coal gangue is ground by the impact and attrition caused by the falling balls.

- Raymond Mills: These are roller mills where a series of rollers rotate, compress, and grind the coal gangue between them. The fineness of the grinding is controlled by adjusting the gap between the rollers.

- Vertical Roller Mills: Similar to Raymond mills, Vertical Roller Mill have rollers that grind the coal gangue between them. They are known for their energy efficiency and ability to produce finer materials.

- Ultrafine Grinding Mills: These mills are designed to produce extremely fine particles and are suitable for applications where a high degree of fineness is required.

Separation:

Various separation techniques may be employed to separate different components of coal gangue based on their physical properties.

For example,

gravity separation or

magnetic separation may be used to separate coal from minerals.

Utilization or Disposal:

The processed coal gangue can be used for various purposes:

- Construction Materials: Coal gangue can be used as a raw material for producing bricks, tiles, and cement.

- Power Generation: In some cases, coal gangue can be utilized as a fuel for power generation.

- Backfilling: It can be used as backfill material in coal mines to support the surrounding strata.

- Other Applications: Depending on the composition and characteristics, coal gangue may find use in other applications.

Environmental Considerations:

Proper environmental management is essential to mitigate any negative impacts associated with coal gangue processing.

This includes measures to control dust, prevent water pollution, and manage waste.

Quality Control:

Quality control measures are implemented throughout the processing line to ensure that the end products meet the required standards and specifications.

Shanghai Clirik Machinery Co.,Ltd. provides a complete set of coal gangue powder processing solutions. Including preliminary design, gangue crusher, gangue grinding mill production and assembly, etc. Feel free to contact us for a quote.