The powder surface coating machine is mainly used for surface modification of mineral powder materials, which makes the application field of mineral powder more and more broad.

The

mineral powder surface coating machine is widely used in the fields of non-metal stuffing or pigments like plastic, rubber, adhesive, macromolecule materials, high polymer composite, functional materials, and dope industries.

Mineral powder surface coating machine can not only improve the compatibility of both non-organic mineral stuff and organic high polymer, enhance the binding force of interfaces, rise the mechanical strength and comprehensive ability, but also increase the stuffing ability of powder, save product cost and add a special physical and chemical property to the product to some extent.

In order to solve the above-mentioned problems in production,

CLIRIK Machinery designed and produced

CLG series powder surface coating machine after several years of research and update.

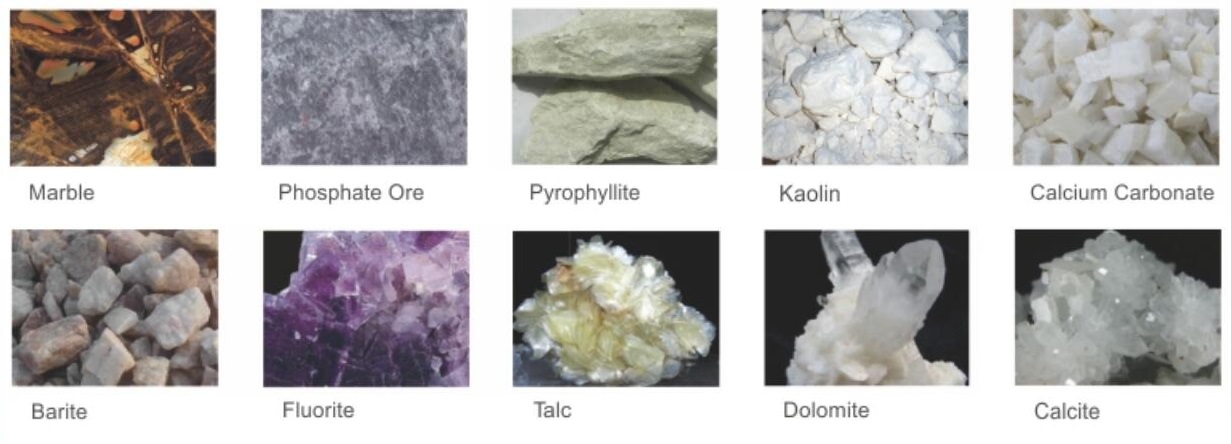

Scope of application

Provided with the unique chamber design, both modification and depolymerization functions, the machine is applicable to modify various materials. It can reach excellent surface modifications for such materials as

ground calcium carbonate (GCC), precipitated calcium carbonate (PCC), kaolin, talcum, wollastonite, mica, white carbon black, zinc oxide, alumina, silicon powder, graphite, magnesium-hydroxide, barium sulfate, illite, clay stone, pyrophyllite, tremolite, etc.

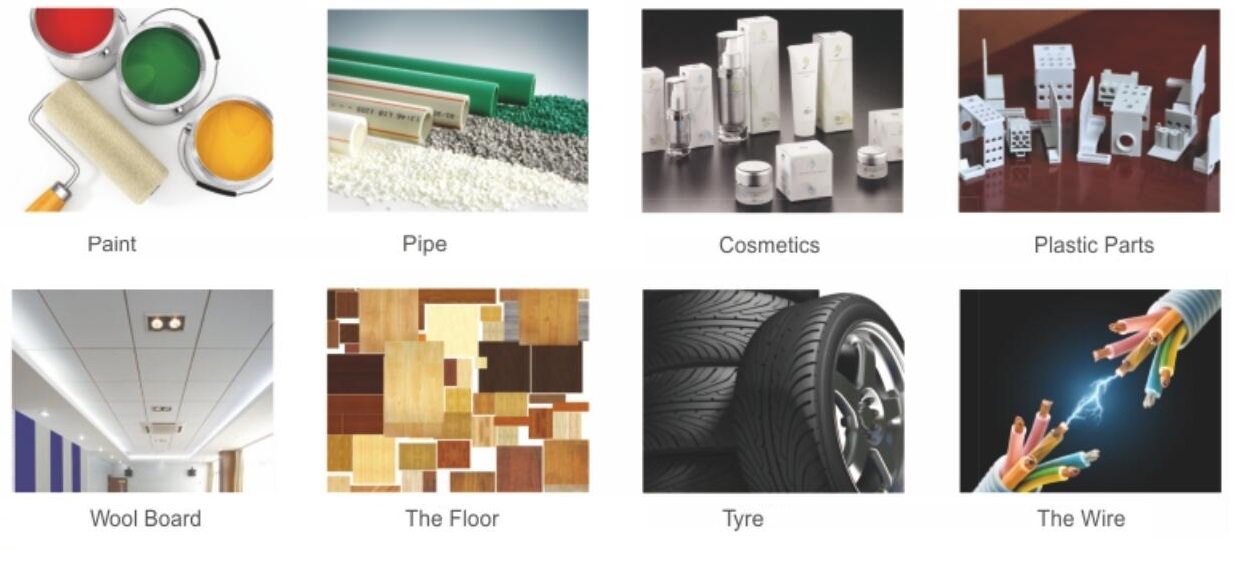

Application field

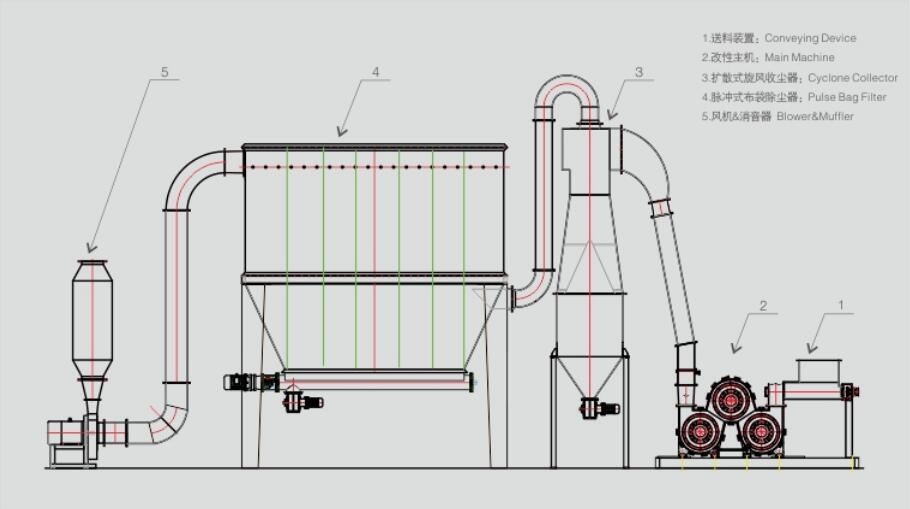

Structure and function

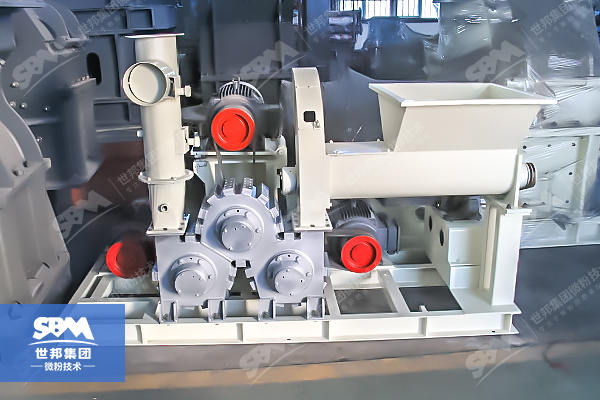

Powder Surface Coating Machine Components:

- ●Hopper: materials enter into a hopper from silo or bags. The humidity of feeding materials should be less than 0.5%

- ●Conveying device: double screws and adjustable speed ensure the stability of material flow

- ●Agent adding system with temperature control:

- The automatic temperature control system, free setting of melting temperature, suitable for various modifying agents in both solid and liquid form.

- ●Main machine: Consisting of 3 modifying rollers in a triangle form, compact design, high efficiency, and stable running.

- ●Cyclone dust collector: diffusion type

- ●Impulse type bag dust collector: new generation pleat filter, with the advantage of little space, large filtration area, high dust removal efficiency, and easy cleaning.

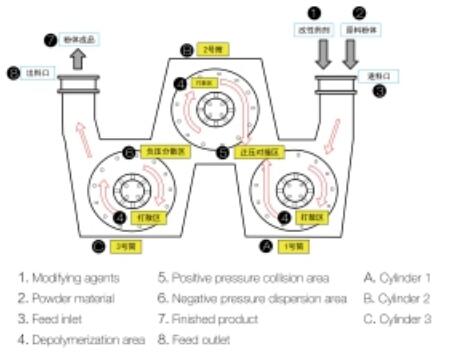

Working principle

The powder surface treatment is mainly completed by means of three modifying rollers. The dry powder and dosed agent are put into the modifying rollers simultaneously. With high-speed rotation, the power and agent are running in the form of a fluidizing vortex. The modification is going on with the heat generated by high-speed shearing, colliding and friction among the rotor, stator, and powder.

CLG powder surface coating machine advantages

- ●Continuous operation, large capacity, suitable for industrialized production on various scales.

- ●High efficiency and less consumption of modifying agent, high covering and active index of powder, energy saving.

- ●Both modifying and dispersion function, suitable for any fine materials, special active effect for material with small proportion and big cubage weight like white carbon, mica powder, and talcum powder.

- ●Powder and agent mixing and running in high speed and vortex, high modifying efficiency, with little change of granulate shape. Keep the original particle shape of the powder.

- ●Running in negative pressure working condition, airtight, no dust leakage, no pollution, good operation condition, low labor intensity.

- ●Operating in heat and cold conditions, no additional heating or cooling system required easy operation.

- ●Independent fluid and non-fluid agent adding system for continuous, stable, and evenly operation.

Evaluation Method of modified Powder Surface

●Active index

H=Weight of floating part in sample 1 total weight of sample

●Measuring contact angle

●Surface strength (surface tension)

●Surface covering rate (diffusing reflection Fuliye divert spectrum method)

Coating Agents

1. Titanate Coupling Agent

The basic types are composite and coordination.

The dosage is 0.1%-0.3% as stuff or pigment.

2. Silane Coupling Agent

It is a low molecule organic silicon compound with a special structure, used for surface treatment of non-organic mineral stuff or pigment.

3. Zirconium aluminate coupling agent

There are more non-organic reaction points for coupling agent

which can enhance the interaction of the surface between no-organic stuff and pigment. It is divided into 7 types, applicable respectively to surface treatment of polyolefin, polyester epoxy resin, nylon, acrylics resin, polyurethane, synthetic rubber, and other non-organic stuffing materials.

4. Organic Chromium Couple Agent

The coupling effect is better in glass-fiber-reinforced plastics.

5. Surfactant

- a. Fatty acid and salt;

- b. Amine salt;

- c. Nonionic surfactant.

6. Organic-silicon

The main items are polydimeth siloxane, organic modified siloxane, and high polymer of organic silicon and organic compound. The organic silicon for organic stuff or pigment is usually polymethy siloxane with active radicals.

7. Saturated Organic Acid And Organic Oligomer

Organic Surface Modifying Agent

Product Specifications

| Model |

Main Power |

Blower Power |

Speed of Shaft |

Capacity |

Weight |

Overall Dimension |

| CLG-200D |

11kw |

2.2kw |

5700 r.p.m |

40-150kg/h |

1t |

3200*600*2200mm |

| CLG-3/300 |

3-18.5kw |

5.5kw |

4500 r.p.m |

500-1800kg/h |

3t |

5800*1800*5600mm |

| CLG-3/600 |

3-37kw |

15-22kw |

2700 r.p.m |

2000-4000kg/h |

10t |

11200*3100*6200mm |

| CLG-3/900 |

3-75kw |

45kw |

2000r.p.m |

4000-7000kg/h |

20t |

21000*3800*6500mm |

Optional Plans

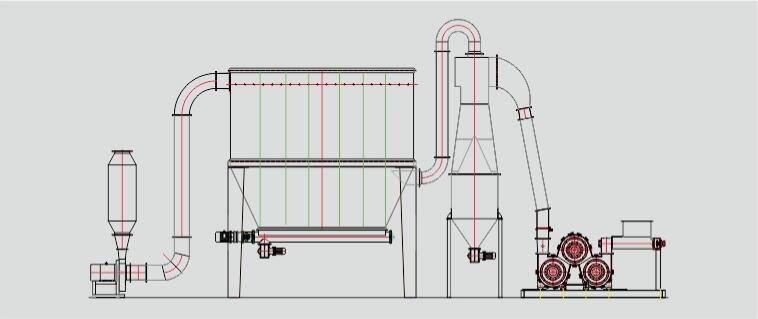

Plan 1: Coating machine

Chart

Customer Site

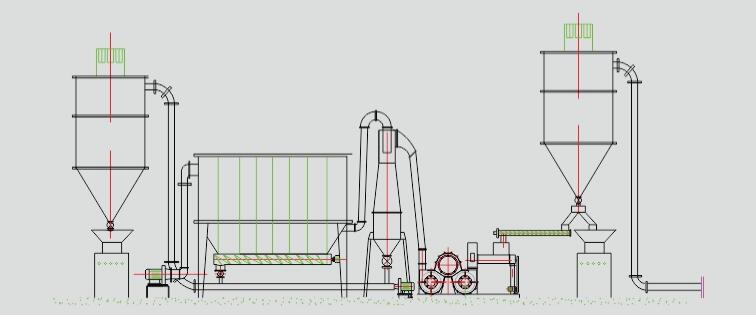

Plan 2: Coating machine+Conveying system+Paking machine

Chart

Customer Site

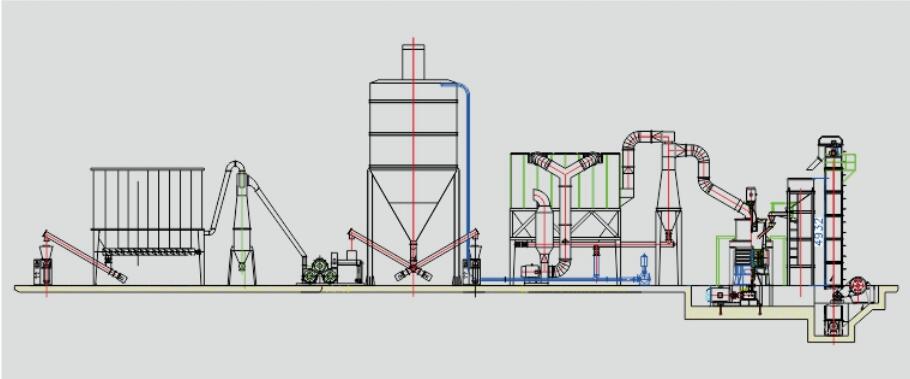

Plan 3: Grinding mill+Coating machine+Conveying system+Paking machine

Chart

Customer Site

WHO WE ARE?

SBM Ultrafine Powder Technology Co., Ltd. is one of the premier manufacturers for equipment in the mining, grinding, coating,packing, recycling and process industries.

With SBM Ultrafine Powder Technology unique knowledge and innovative solutions, SBM helps many customers improve their operational efficiency, reduce risks and increase profitability.

SBM Ultrafine Powder Technology products can be divided into

crushing equipment, grinding equipment, drying equipment, screening equipment, conveying equipment and

auxiliary equipment.

SBM Ultrafine Powder Technology products have passed the quality system certification of ISO9001:2008, and the European CE certificate.

SBM sincerely welcome local distributors join us together to shape SBM Ultrafine Powder Technology brand and delivery high value-added equipment products in the global market around world.

SBM Ultrafine Powder Technology is an international high-tech enterprise which integrates the research and development, production and sales.

HOW TO BUY?

- 1. Engineering project design

- 2. Equipment purchasing and manufacturing

- 3. Engineering project construction

- 4. Installation and Commissioning service

- 5. After-sales service

WHICH MODELS CAN BE SELECTED FOR PROCESSING Ultrafine POWDER?

HGM grinding mill: 74-5 micron(200-2500 mesh); D97=5 micron

CLUM vertical roller mill: 20-5 micron(600-3000 mesh); D50=2 micron D97=4 micron

HOW TO GET THE LATEST QUOTATION?

You can leave a message online or contact

SBM Ultrafine Powder Technology directly:

WhatsApp: +8613512155195

India

India

Vietnam

Vietnam

China

China