The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

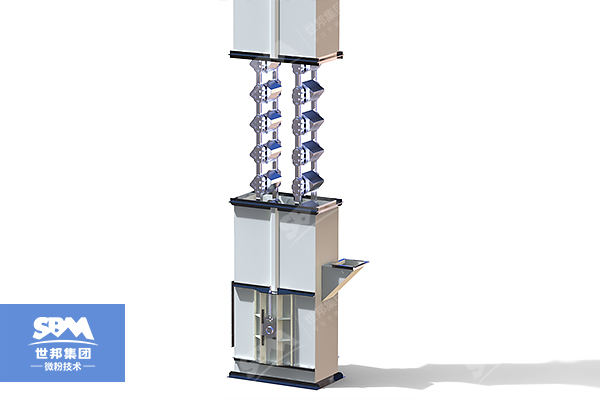

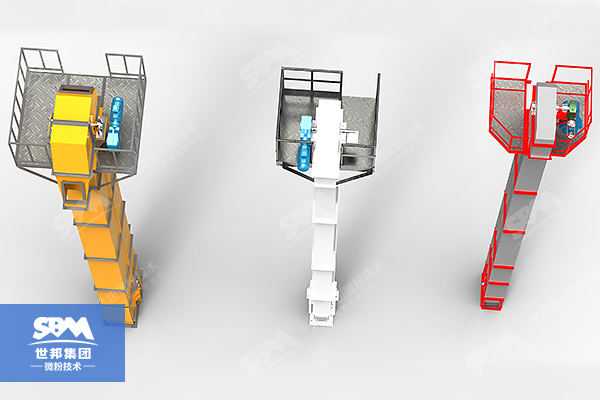

Applicable materials: Granule and small lump of no rub or small rub, such as coal, cement, gravel, sand, fertilizer, food, etc.

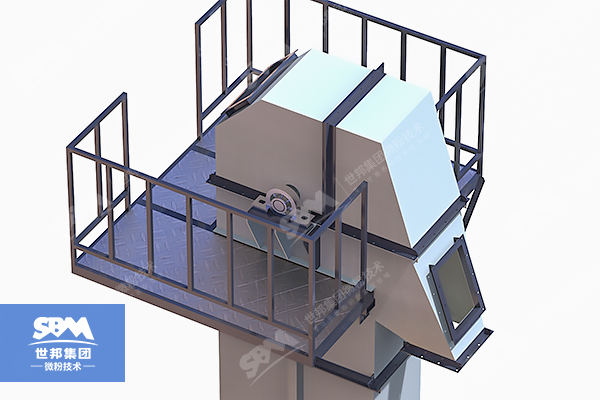

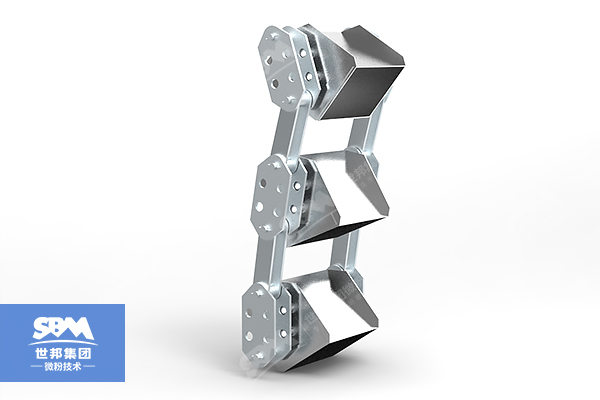

Product features: Bucket elevator consists of frame, drag part (conveyor chain), hopper, drive wheel (head wheel), feeding inlet (input inlet), and discharging outlet (output outlet).

| Link Chain Bucket Elevator Model | TH160 | TH200 | TH250 | ||||

| Hopper Type | ZH | SH | ZH | SH | ZH | SH | |

| Capacity/(m³/h) | 15.77 | 24.97 | 17.87 | 28.6 | 31.43 | 48.19 | |

| Hopper | Volume (L) | 1.2 | 1.9 | 1.5 | 2.4 | 3.0 | 4.6 |

| Interval (mm) | 500 | ||||||

| Chain | Round Steel Diameter*Pitch(mm) | 14*50 | |||||

| Single Load(KN) | ≥190 | ||||||

| Hopper Running Speed/(m/s) | 1.2 | 1.2 | 1.2 | ||||

| Drive Sprocket Rotation Speed(r/min) | 69.71 | 63.22 | 44.11 | ||||

| Conveying largest size(mm) | 20 | 25 | 30 | ||||

| Link Chain Bucket Elevator Model | TH315 | TH400 | TH500 | TH630 | |||||||

| Hopper Type | ZH | SH | ZH | SH | ZH | SH | ZH | SH | |||

| Capacity/(m³/h) | 35 | 59 | 58 | 93 | 81 | 130 | 145 | 210 | |||

| Hopper | Volume (L) | 3.75 | 6 | 5.9 | 9 | 9.3 | 15 | 15 | 24 | ||

| Interval (mm) | 512 | 688 | |||||||||

| Chain | Round Steel Diameter*Pitch(mm) | φ18*64 | φ22*86 | ||||||||

| Single Load(KN) | ≥320 | ≥480 | |||||||||

| Hopper Running Speed/(m/s) | 44 | 37.6 | 39.7 | 35.8 | |||||||

| Conveying largest size(mm) | 35 | 40 | 50 | 60 | |||||||

India

India

Material: Limestone

Fineness:800 mesh

Capacity: 5 t/h

Vietnam

Vietnam

Material: calcium carbonate

Fineness:2500 mesh

Capacity: 10 t/h

China

China

Material: Bentonite

Fineness:200 mesh

Capacity: 10-15 t/h

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.