Air conveying system takes roots blower as the air source. It is designed specifically for close distance and continuous transporting.

Generally, horizontal transporting distance is under 300m, vertical distance is under 30m. It is suitable for conveying powder specific gravity less 1.3, fineness less 60 mesh, moisture content under 5%, under the highest instantaneous temperature under 250°C working conditions, the maximum conveying ability is 60 t/h.

It also can be used in nesting conditions for single-point or multi-point requirements.

The equipment has features of long life, low operation and maintenance costs, small size, easy control.

It is widely used in mining, building materials, coal, chemical, and other industries.

Air conveying system features

- ●Variable arrangement of the pipe makes the production workflow process more reasonable.

- ●The system is sealed and leads to little flying dust, it benefits for environmental protection.

- ●Few movement parts, convenient maintenance, automatic control can be realized easily

- ●High efficiency of transportation reduce the cost of packing, loading, and unloading

- ●Make the material avoid being damped, polluted, damaged, and mixed with other material, the quality of conveying is assured

- ●Various operation processes can be realized meanwhile for the conveying, such as mixture, crush, grade, dryness cooling, and dust collection.

- ●Send the material from a couple of places to one place and from one place to a couple of places, realize far distance operation

- ●For the material with erratic chemical character, can adopt inert gases conveying.

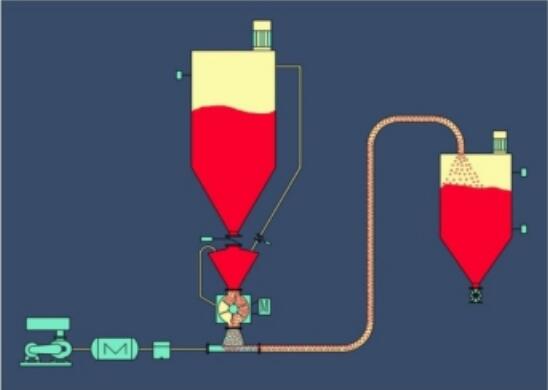

Working Principle

Air conveying system adopts the principle of gas-solid flow fluidization, jet technology, combined with differential pressure principle, to finish this working progress. Taking the electric rotary feeder as the feeding device, the material is evenly put into the mixing chamber. At the same time of fluidization, the high-speed of airflow is produced by roots blower sends the material into acceleration chamber, and the suspension flow goes into the silo through conveying pipeline. After the filter is separated, the powder falls into the silo while gas release into the atmosphere. The powder conveying purpose is achieved.

Product Specifications

| Model |

CLXB-75 |

CLXB-100 |

CL XB-150 |

CLXB-200 |

CLXB-250 |

| Capacity(t/h) |

1-4 |

3-9 |

10-15 |

15-20 |

18-25 |

| Blast capacity(m³/min) |

3-9 |

9-20 |

20-36 |

36-50 |

50-70 |

| Inlet pipe diameter |

DN100 |

DN133 |

DN125/DN159 |

DN219 |

DN273 |

| Velocity in pipe (m/s) |

13~16 |

| Pressure(kpa) |

≤98 |

| Body material |

Cast iron, cast steel, stainless |

| Motor(kw) |

3-15 |

15-30 |

35-65 |

70-90 |

90-110 |

WHO WE ARE?

SBM Ultrafine Powder Technology Co., Ltd. is one of the premier manufacturers for equipment in the mining, grinding, coating,packing, recycling and process industries.

With SBM Ultrafine Powder Technology unique knowledge and innovative solutions, SBM helps many customers improve their operational efficiency, reduce risks and increase profitability.

SBM Ultrafine Powder Technology products can be divided into

crushing equipment, grinding equipment, drying equipment, screening equipment, conveying equipment and

auxiliary equipment.

SBM Ultrafine Powder Technology products have passed the quality system certification of ISO9001:2008, and the European CE certificate.

SBM sincerely welcome local distributors join us together to shape SBM Ultrafine Powder Technology brand and delivery high value-added equipment products in the global market around world.

SBM Ultrafine Powder Technology is an international high-tech enterprise which integrates the research and development, production and sales.

HOW TO BUY?

- 1. Engineering project design

- 2. Equipment purchasing and manufacturing

- 3. Engineering project construction

- 4. Installation and Commissioning service

- 5. After-sales service

WHICH MODELS CAN BE SELECTED FOR PROCESSING Ultrafine POWDER?

HGM grinding mill: 74-5 micron(200-2500 mesh); D97=5 micron

CLUM vertical roller mill: 20-5 micron(600-3000 mesh); D50=2 micron D97=4 micron

HOW TO GET THE LATEST QUOTATION?

You can leave a message online or contact

SBM Ultrafine Powder Technology directly:

WhatsApp: +8613512155195

India

India

Vietnam

Vietnam

China

China